Work package 4 – Processes for making high value rolled steel products

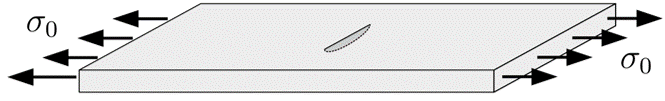

This work package addresses how to process raw steel made from hydrogen reduction processes into high value steel products, particularly rolled steel slabs. This work is needed because steel companies are rethinking the design concepts for their next generation of hot rolling mills. E.g. Using Hybrit raw iron as an input, SSAB aims to design mini mills that produce thinner steel slabs using less energy. Therefore, this work package aims to provide input into the design of mini mills. The work package takes an overarching ICME approach, with its projects developing models at different scales as well as characterising the performance of steels. Projects will then collaborate to integrate these models and performance information in order to shape a more holistic perspective of the process (ICME) and how the design of the rolling process affects the quality and performance of steel product outputs.