The fracture toughness performance of rolled steels

ICME Modelling of mini mills: starting from the fracture toughness performance of rolled steels, and considering the effects of segregation, this project will compare traditionally produced cast steel and fossil free cast steel - and provide this steel-performance input to the other projects in work package 4.

Background

Sweden today produces high value specialist steels, including high-strength steels. The aim of Swedish companies making the transition to fossil free production systems is to continue to produce high value specialist steels - despite the changes in the product production processes. Specialist steels are designed for particular types of applications. High strength performance is one example. There are therefore several specialist steel grades, each of which have been designed to perform well under particular conditions where high strengths are needed.

Designers of products that need high strength properties, then use Eurocode 3 - Design of steel structures, EN 1993-10/12, to select a steel grade: this standard provides tables that simplify the steel grade to a material toughness parameter, and with fracture toughness limitations tabulated for various operating temperature, loads and plate thickness.

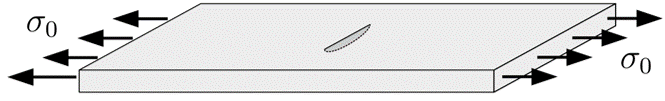

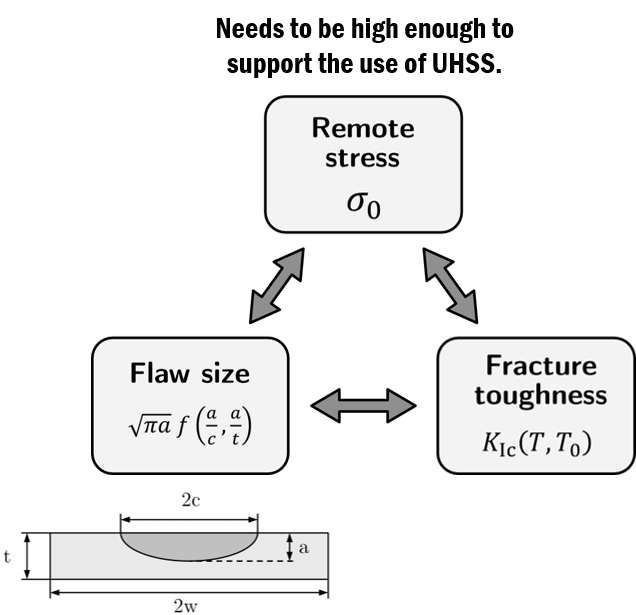

Fracture toughness is a measure of the material’s resistance to fracture, which governs the critical length a crack can grow to before the crack/material ruptures. For a given material, fracture toughness is particularly affected by temperature. Furthermore, fracture toughness is also affected by the homogeneity of the material's microstructures - with segregation of alloys and inhomogeneity adversely affecting fracture toughness.

Workplan

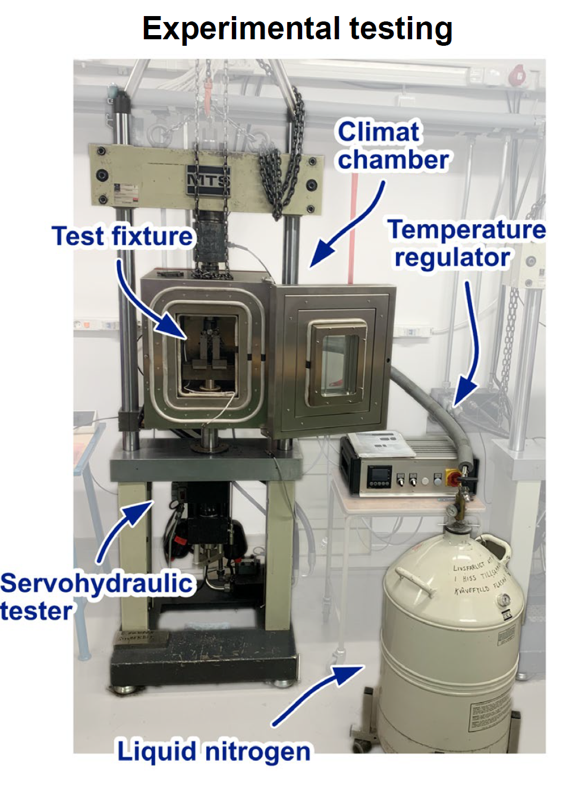

This project will therefore assess the fracture toughness of various steel grades, comparing steels produced by traditional processes and via greener processes e.g. scrap-based EAF-produced. Tests in different atmospheric environments (air/hydrogen charging) are also possible. Testing will be undertaken in accordance with ASTM E1921 − 22 (Brittle failures).

Relation to other projects in this workpackage

This fracture toughness information will be input to the other projects in this work package.

This is possible because the critical failure of a fracture is related to the stress applied to the material.

People in this project

SSAB's Torbjörn Narström will also be active in this project.