Rheology of fossil-free slags

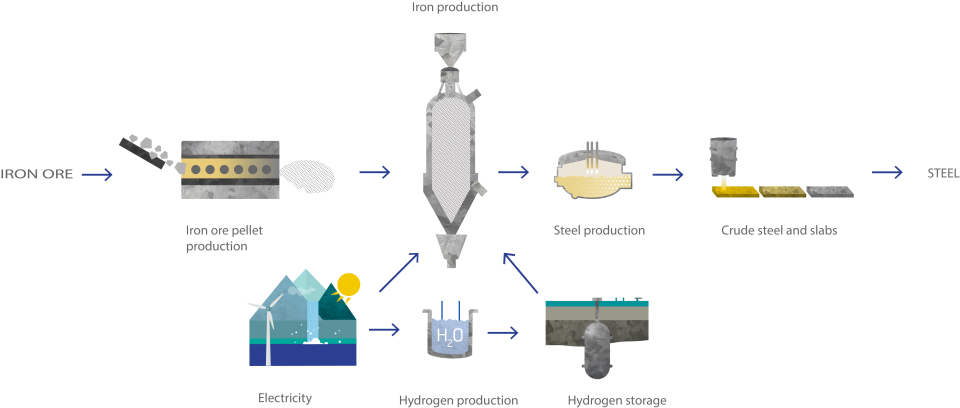

“Slag” is a term for the byproducts generated during iron or steel manufacturing processes. To minimise waste, and be more circular, Swedish iron and steel makers actively manage their iron/steel manufacturing process in a way that also produces slags that can be upcycled into other valuable end-products. Asphalt is one common example. Shifting to hydrogen based steel production however will lead to a different composition of slag system. This may lead to a very different rheology property (e.g. viscosity), which may affect whether the slag can be upcycled.

Aims

This project aims to:

- Understand the EAF slag rheology behavior after Hydrogen-reduction processes

- Determine the composition, structure and properties of slags produced via H2 reduction-EAF systems.

- Develop experimental models and simulations to contribute to producing slags in a way that they can be upcycled to valuable products

Project activities

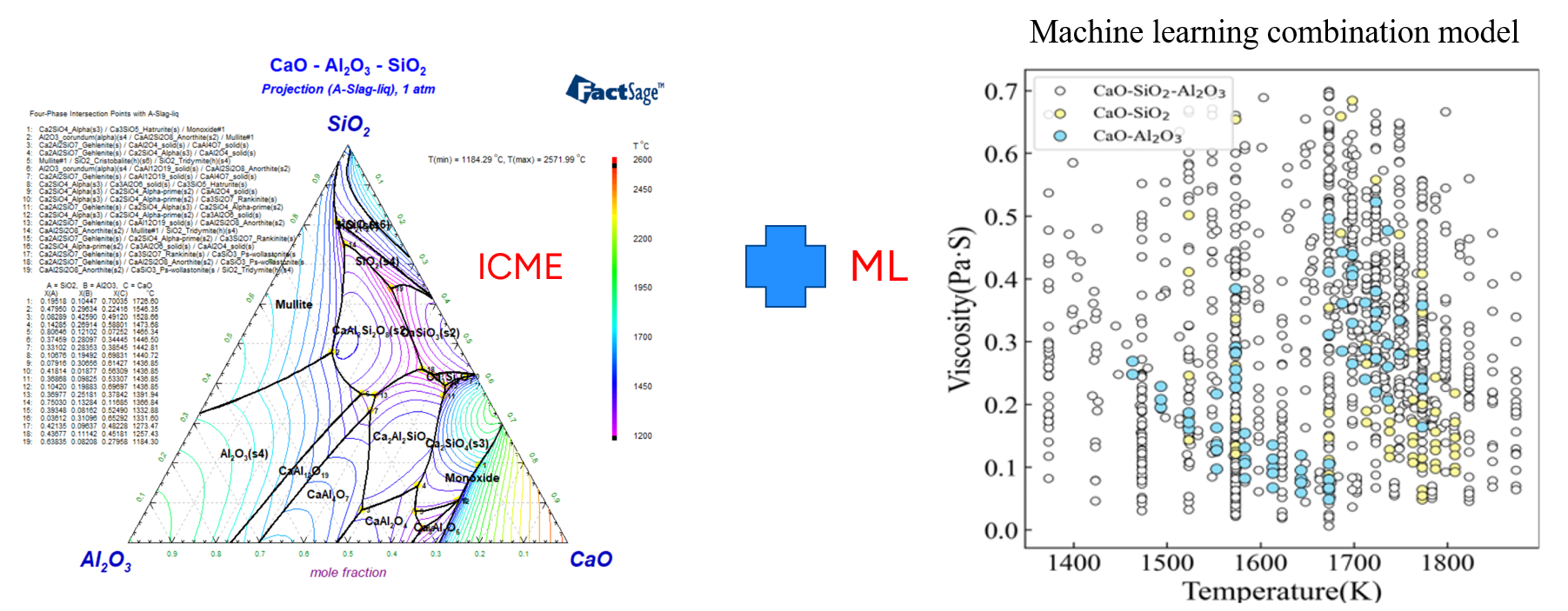

To achieve the aims, this project will undertake a range of experiments. The Property of the slag will be determined via viscosity measurements. The structure of the slags will be determined from Raman, NMR, XRD and microscopy studies. Thereafter, a predictie model will be developed using a combination of ICME & ML.

People in this project