Developing hydrogen-tolerant steels

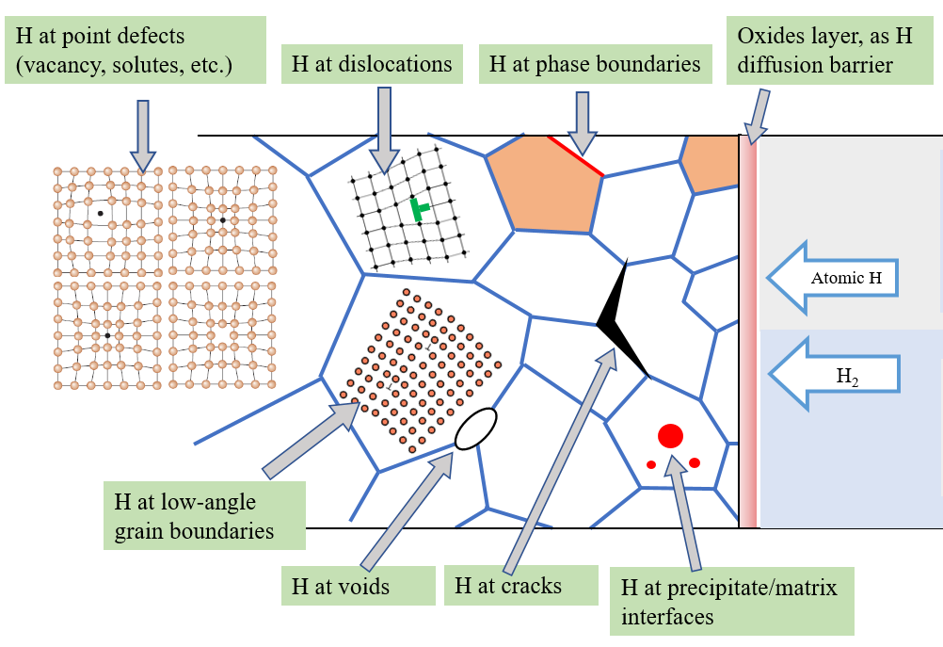

Hydrogen atoms and gas can penetrate into steels, and interact with the structures within the steel. This often causes internal stress and strains, which embrittle the steel. Such hydrogen embrittlement reduces the working life of the steel. Developing an understanding of the underlying microstructural defects and elemental segregation for trapping hydrogen, we propose to develop mechanisms to mitigate hydrogen embrittlement. And, use these mechanisms as the basis for designing hydrogen-tolerant steels. That is, steels that have a longer lifetime when in service in hydrogen environments.

About this work package

This project's goals and work plan are:

- To gain a fundamental understanding of microstructural defects and elemental segregations for H trapping to mitigate hydrogen embrittlement

- To develop insights into mechanical responses of controlled microstructures under hydrogen-rich environments by ex-situ & in-situ characterization techniques

And, based on such fundamental knoweldge

- To use CMD tools to explore the design of microstructures with high hydrogen tolerance.

Current work

To achieve our goals, in addition to a literature survey, we are currently charging steels with hydrogen and/or duterium and then studying the steels using various materials characterisation and mechanical properties techniques e.g. tensile testing, hardness testing and nano-indentation.

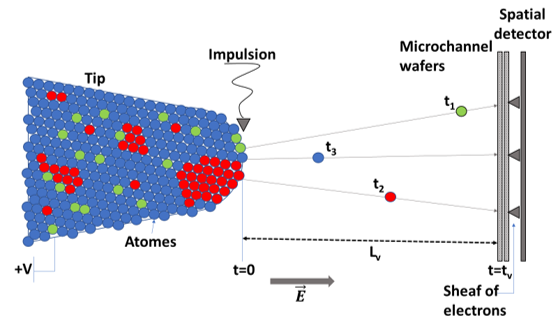

We are also developing methodologies to determine where hydrogen is located within steels using Atom Probe Tomography (APT). APT is a combination of projection imaging and time-of-flight mass spectrometry, where 3D images of the chemical composition of steel are mapped, atom-by-atom with near-atomic spatial resolution. APT offers a powerful combination of spatial (sub-nm) and chemical sensitivity (up to several atppm), with, importantly, equal detection efficiency to all elements and isotopes. (Equal detection efficiency is particularly important in this research because H particularly difficult to measure with other imaging techniques.) A single sample can yield information comprising several million to hundreds of million atoms

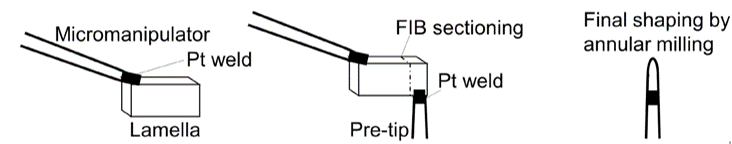

The APT technique involves identifying areas of interest within the steel and using Focal Ion Beams to prepare a sample.

Therafter, the APT technique maps the steel, atom by atom.