Modelling microstructural evolution during hot-rolling

ICME Modelling of mini mills: starting from microstructures

Background

A key element of Swedish steel company's business model is producing high grade steels. Thus, as input to the design of future mini mills, several aspects of the mini mill design need to be assessed from the perspective of producing high grade steels. Several workpackages address this issue, with this particular project focusing the evolution of microstructures within the steel, including precipitates. Other projects will focus on other aspects - with all projects collaborating.

Project objectives

The objectives of this project are to:

- Develop a model for precipitation during hot rolling, accounting for varying temperature and plastic deformation

- Use that model study the precipitation of carbonitrides in micro-alloyed steels

Workplan

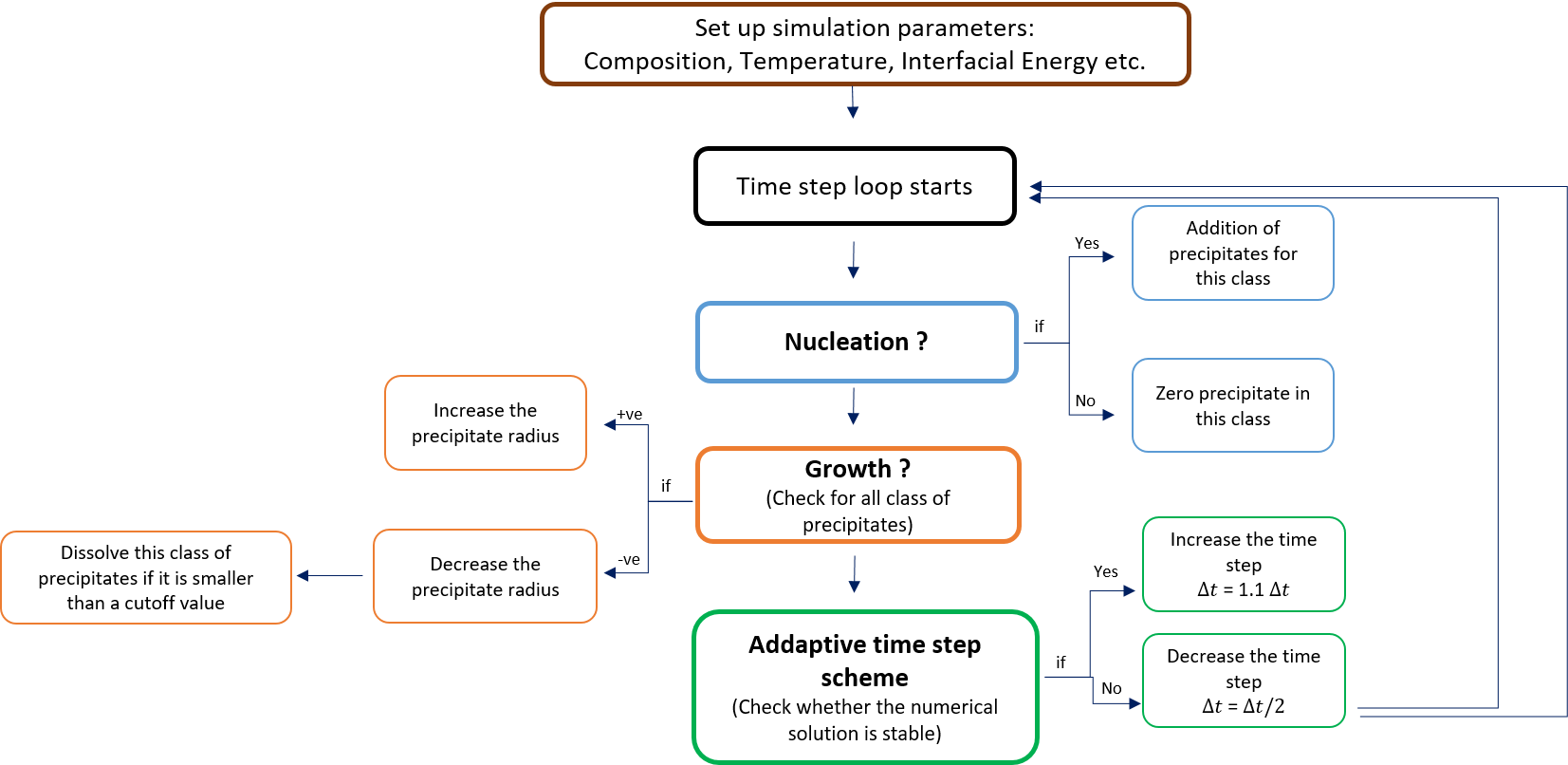

- Implement a model based on the Numerical-Kampmann-Wagner (NKW) framework

- Integration that NKW-based model with with thermodynamic and kinetic databases

- Couple plastic deformation effects into the model

- And, depending on how well the plastic deformation model performance, consider also including a phase-field implementation accounting for deformation